NSW Steel Pipe Sheet Pile Stud Method

NSW Steel Pipe Sheet Pile Stud Method is a method by using Deformed Bar Stud on joint part between top plate and steel pipe sheet pile edited on Road Bridge Instruction・commentary Ⅳ lower structure.

This method is a method that NSW Deformed Bar Stud which is superior in weldability is welded directly to steel works (steel pipe sheet pile・steel plate) and at the same time quality improvement and lower cost・man hour reduction by using monitoring system and exclusive ferrules (arc shield) can be realized.

Applied portions

On the steel pipe sheet pile base like chart above, this method is used to joint pile cap portion (footing concrete) and side wall of the steel pipe sheet pile.

Characteristics (Low costs ・ Man hour reduction ・ High quality)

(1)Construction work with stud welding

- Even in the humid open caisson, stable welding quality is gained.

- Because of less welding fume, load to workers can be reduced.

- Man hour can be shortened than other methods.

(2)Monitoring for all welding process

- Quality can be confirmed while welding with monitoring equipment.

- Color check and/or non-destructive test like ultra sonic test after welding is unnecessary.

- Because more observation and control items are set up with the monitoring equipment of this method than ordinal welding monitor, quality is controlled more severely.

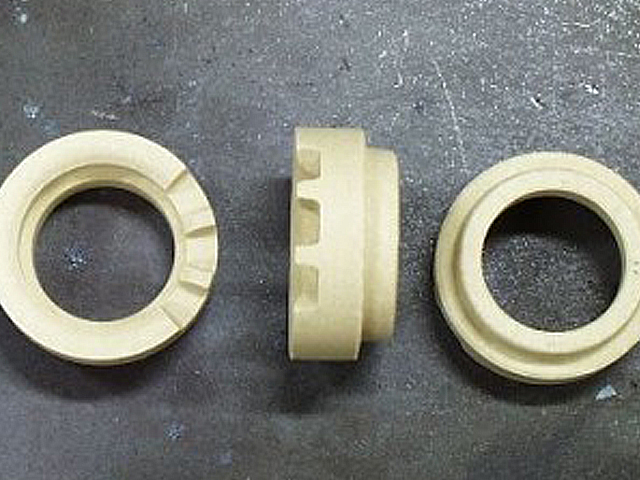

(3)Exclusive Vertical Ferrule (arc shield)

- Based on abundant construction experiences, Exclusive Vertical Ferrule which NSW developed are adopted.

Monitoring equipment

Exclusive Vertical Ferrule

Under construction in open caisson

Stud welding

Stud welding

Inside open caisson after construction

Tokyo branch office: 81-(0)44-589-9515

Chubu branch office: 81-(0)566-45-5241

Osaka branch office: 81-(0)6-6385-2332

Chugoku branch office: 81-(0)82-532-1785