Stud Welding is

Everything, from the history of stud welding to the methods used!

History of Stud Welding

Stud welding is a method to weld so-called stud bolt automatically onto work piece by arc welding etc. without punching or tapping process. From the nature of the work, this method is sometimes called welding method.

Now Pins, Bolts and large variety shapes of metal strips like rectangular strips can be welded on the work piece.

It is said that this welding method was first used at H.M shipyard in Portsmouth in 1918 (Taisho 7).

At first, a light welding tool, (equipped with electromagnetic coil which lifts stud inserted to the top), was used. Through this experience, L・J・Steel and H・Martin made progress to the automatic equipment which welded stud to the steel plate to some success.

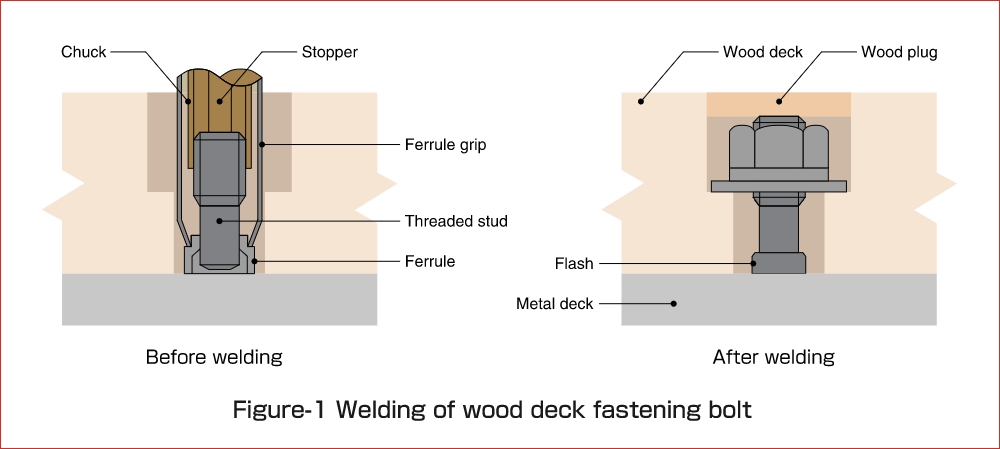

On the other hand, at the Navy Arsenal in the USA in 1939 (Showa 14), T・Nelson applied stud welding to weld metal round bars or threaded bolts to metal deck on the aircraft carrier to fix wooden plates. It was the firstly adopted so-called arc stud welding. Since then, Gregory Industries Ltd (now, Nelson Stud Welding Ltd) proceeded research and development then they made a rapid progress.

In Japan, from the beginning of Showa, brass studs were greatly welded as a name of Drawn Arc welding to fix electric wiring and electric appliances to metal plates inside warships and other ships.

Besides, after World WarⅡ, stud welding method was introduced by Nelson Stud Welding Ltd in the USA and Crompton Parkinson Ltd in England then it was made a rapid progress. Now not to mention in ship building, it becomes to be used in construction, bridge, automotive and other industries.

Head Office: 81-(0)44-333-3636