SC Pile Stud Method

SC Pile Stud Method can reduce man hour because of shorter welding time as compared with general flare welding method and can reduce damage to pile.

SC Pile Stud Method (GBRC Performance Certification #12-19) is a pile head joint method by which Pile Stud can be welded to SC Pile which is equipped with a size larger end plate (widen plate) than pile diameter. In 2012 we were granted Construction Technology Performance Certification from General Building Res. Corp. or GBRC.

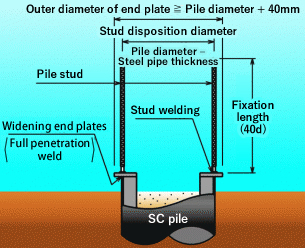

(chart: Pile Joint Structure Chart of this method)

Applicable portion

Pile head end plate of SC pile which is equipped with larger end plate (widen plate) than pile diameter exclusive to this method

| Pile specification | Widen end plate specification | Stud specification |

|---|---|---|

| Pile diameter 400~1200 Steel pipe thickness 4.5mm~25mm Steel pipe material SKK(STK)400,490 |

End plate thickness 19mm End plate outer diameter Pile diameter + more than 40mm Material SM490A,B,C SN490B,C |

Applicable diameter D13~D25 Material KSW490(JISG3112 SD345) Disposition diameter Pile diameter – Steel pipe thickness (Center of steel pipe thickness) |

Characteristics

- Man hour can be reduced greatly because of shorter welding time per one reinforcement bar.

- Damage to pile is small because of little heat input as compared with conventional method (flare welding).

- Construction carrying-out soil is less because of small excavation area around pile head.

- Steady welding quality can be secured because of clear quality control standard.

Construction・Inspection procedure summary (extract)

Preparation before construction

Main construction (Stud welding)

Product inspection (Appearance・Dimensions check, slant test, bend test)

Tokyo branch office: 81-(0)44-589-9515

Chubu branch office: 81-(0)566-45-5241

Osaka branch office: 81-(0)6-6385-2332

Chugoku branch office: 81-(0)82-532-1785