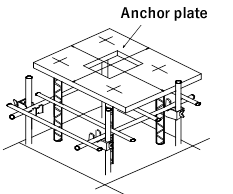

Base Anchor Stud Method

Base Anchor Stud Method (Stud welding type, steel column leg method for erection)

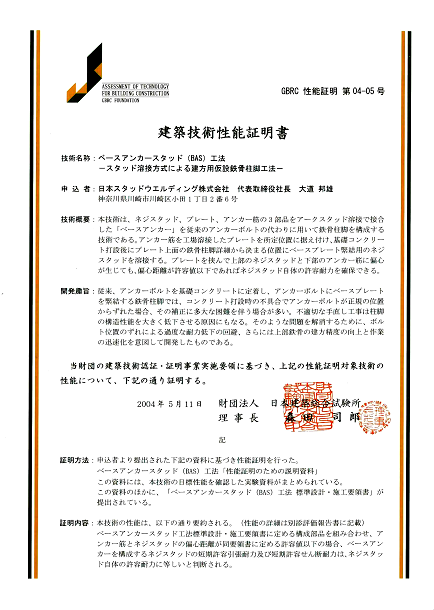

GBRC Performance Certification #04-05

Base Anchor Stud Method is a method by which improvement of accuracy of upper frame construction, quick work, shorter man hour and evasion from proof stress deterioration accompanying with positional displacement of anchor bolt can be realized when steel pillar is built on to the concreted base.

What is base anchor stud method?

Method which realizes improvement of accuracy on upper iron framework construction, rapid work, shortened schedule and avoidance of yield strength drop accompanying anchor bolts correction when steel columns are built on the bases where concretes were cast.

Problems on the conventional method

Even if anchor bolts are placed correctly, they tend to move when concretes are cast.

If they are out of the correct position:

- Remove base concrete around anchor.

- Bend anchor to the correct position.

- Cast concrete again, and then build steel column.

Correction work is difficult and takes man-hours.

Besides, inadequate correction work deteriorates structural function of the column base.

(Right chart: conventional method)

Characteristics of the base anchor stud method

- Because threaded studs are welded after base concretes are cast, there is no positional movement, so accuracy of upper iron framework construction improves.

- Because there is no need of correction work, risk of yield strength drop can be avoided.

- Shortened total man hour can reduce costs.

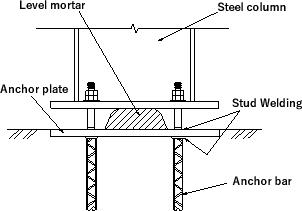

(Right chart: Base Anchor Stud Method)

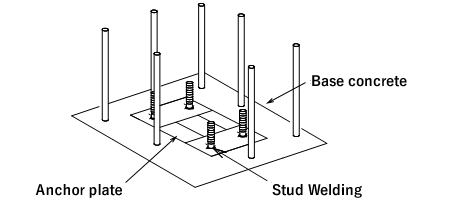

Summary of base anchor stud method

1.Manufacture of anchor plate (in factory)

Build up base plate beforehand.

2.Installation of the anchor plate

Install the anchor plate on the base concrete so that base plate can be seen.

3.Threaded stud welding (at site)

After base concretes are cast, mark the position of the steel column base correctly on the anchor plate, and then weld threaded stud.

Method using stud welding

- Conventional anchor bolt diameter can be switched to threaded stud as it is.

Because joint efficiency of stud welding is 100%, only by switching, equivalent yield strength to the conventional anchor bolt can be secured. - Threaded stud ranging from M16 to M36 can be welded at site.

Besides, wide range of applications can be corresponded to regardless of column base figures. - Only constructor who received special training (BAS site engineer) performs stud welding.

- Both deformed bar Studs (anchor reinforcing bar) and threaded studs with reliable mechanical strength and weldability made by NSW are used.

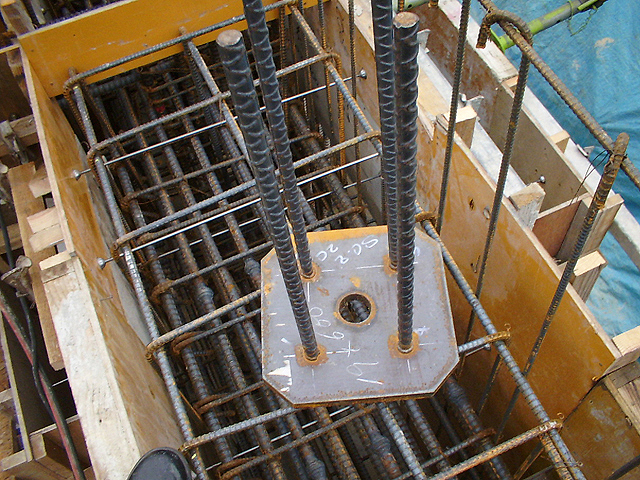

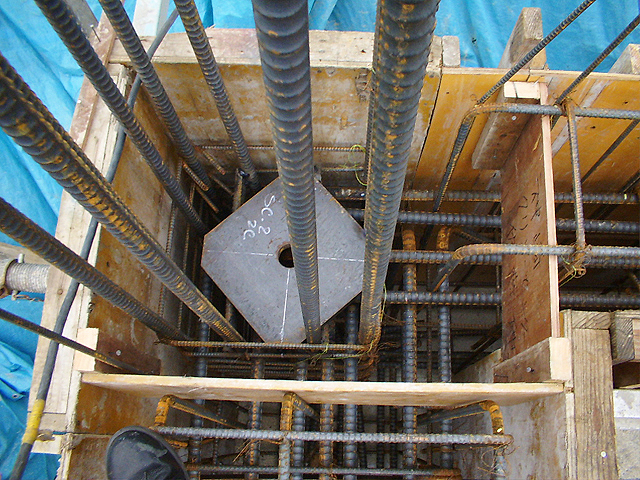

Site work example of base anchor stud method

Anchor plate (already manufactured)

Installation of anchor plate

After base concretes were cast

Welding point marking

Threaded stud welding

Construction completes

Construction Technology Performance Certification granted

GBRC Performance Certification #04-05)

Tokyo branch office: 81-(0)44-589-9515

Chubu branch office: 81-(0)566-45-5241

Osaka branch office: 81-(0)6-6385-2332

Chugoku branch office: 81-(0)82-532-1785